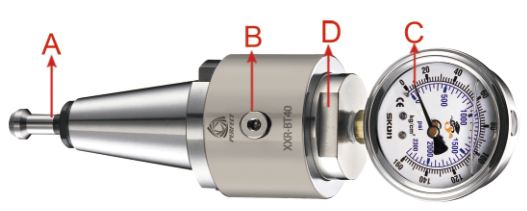

XXR-BT40 Spindle Force Dynamometer

Characteristic

Model : XXR-BT40

Model : XXR-BTSpindle Force Dynamometer

※ Product Features: Hydraulic mechanical structure, high stability

※ Specifications Instructions:

1. Verify pull force gauge bolt specifications on with four claw specifications correspond.

2. Rally and the front spindle taper portion wipe clean,

Rally to clamp.

3. In response to the specifications of each knife, pull range as follows:

Spindle Force Dynamometer

XXR BT-40 Spindle Force Dynamometer

Model | Measuring range | Weight |

BT40-45° | 0~160kg/㎠ tolerance±2.4KG | 4.3KG |

BT40-60° | ||

BT40-90° | ||

CAT40*45° | ||

CAT40*60° | ||

CAT40*90° | ||

ISO40-A | ||

ISO40-B | ||

MAZAK-40 | ||

JIS6339-40 | ||

DIN40 | ||

SK40 |

a: Check if the pre-pressure is in the available condition before using.

Inspection methods:

1. Pointer is not at zero, and there is left pre-pressure

2. Manually check the pressure gauge and if the

body turns

if so, it means there is left pre-pressure.

Otherwise,

if don't, that means there is no

pre-pressure.

b: Method of reloading pre-presssure of dynamometer

1. Remove the screw B.

2. Loosen the pull stud A and loosen it again.

3. Push the pull stud A inwards (so that the oil level is reduced).

4. Fill R68 hydraulic fluid from hole B and then tighten the screw B.

5. Tighten the pull stud A. In the same time, Pointer C will be moving upward.

As the pull stud A is fully tightened, the proper pressure indication will be

between 10 to 30kg.

If it is over 30kg, loosen Screw B and let the indication be 10 to 30kg

c: Method of dynamometer dial indicator reading

1. The inner area of the dynamometer 10.00875 m㎡, so when the indication

times 10 is the correct pulling force.

2. An unit of dynamometer equals to 10kg

3. The digital dynamometer uses the Newton as 1 unit. (1kg = 9.8 N)

d: Method of pull stud replacement

1. Use the adjustable wrench to clamp the seat of "D"

2. Turn the A lever ("D" to hold )

3. Replace the new lever A and lock it again.

4. Check the preload again, if the preload is normal,

you can continue to use it.